Fabricademy Week 4: Bio dyes & Bio plastics

This class focused on researching materials and different naturally sourced dyes which are alternatives to the current synthetic shop-bought ones. Our Gklobal tutor this week was Cecilia Raspanti.

We were able to explore a wide range; from natural dyes using found plants or powdered natural pigments and bacteria, to making bioplastics from animal and plant bases using the natural pigments to colour these, to experimental dyeing with bacteria.

We used DIY recipes from industry experts as well as those found on the internet. We also experimented on many materials.

Assignment 1: Produce at least one natural dye, modifying it’s colour and mordanting it in different ways to dye at least 2 different categories of fibres.

On this page below shows my research into natural Dyes.

Post 1 – Part 1, 2, 3 (assignment continued on plant dyes here)

Post 2 – Part 4 (assignment continued on plant dyed textiles into products)

Assignment 2: Explore dyeing with bacteria of different fibres and bacteria > unfortunately there wasn’t any opportunity to do this topic within the course. We did do an extracurricular workshop, so here it is added as separate post , with some of the final images still to be added of the final bacteria dyed pieces

Assignment 3: Bioplastics

This page also shows some experiments with gelatin bioplastic and also Kombucha growing.

Here is my sub-post showing my first experiments with bioplastic using ingredients like cornstarch and agar.

Assignment 1: Natural Dyes and pigments – 18th to 23rd October

Dyeing yarns and fabric have always been fun for me as I can remember doing so many tests at university. It was great that this was a group project too.

Stage 1:

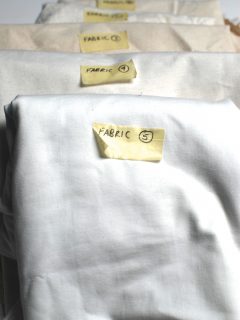

- Source and find a selection of different fabrics.

- We hade 5 fabrics and 2 fibres/yarns

- Label these & note their properties

- All our fabrics were plant based

- Our yarns were…

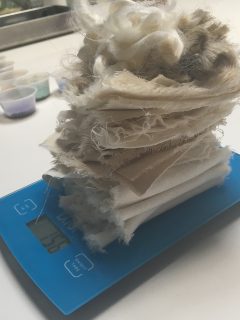

- Cut swatches, 10x10cm, of each of the fabrics

- It was a good size to measure out and also to get the feel of the fabric

- Make 10 sets of swatches to test on the various dyes

- Separate these into stacks of each of the 5 fabrics and 2 yarns

- Mordant all fabric swatches in one batch

- We used the Alum mordant (link to PDF of recipes below)

I decided to collect the data on an Excel/Google Spreadsheet so that we could document our findings as a group and also as we continued throughout the week. Here is a screenshot of our scientific research, with a few details to add.

To view the PDF file, please click here.

We have rows of data which correspond to the names and weights of the fabrics before and after, as well as columns showing the time they went into and out of the dye pots. We also took notes of the water temperature, weight of the natural pigments, size of swatches before and after and also the change in properties.

Stage 2:

- Prepare the dyes.

- Follow instructions from the Lecture PDF or online sources

- Add in Fabric “stacks” to Dye pots as we went

- We approximated the times we put these in and took them out of the pots based on lunch times and lectures!)

- Leave for 24h+ (Further details on PDF)

See our gallery of photos below. I have also created a short video (via flipagram) running through our stages for ease of viewing

Problem: We discovered that we had missed the crucial step of scouring!

Despite this, many of the colours held fast and turned out to lovely shades.

Because of this, I decided to do start my own test using 100% cotton yarn and lace, using the scouring method.

Final layout and deign of the dye swatches to be added

Plant Dyes > Post details here

Part 1 – Making plant dyes

Part 2 – Home natural dye experiments – preparation

Part 3 – Home natural dye experiments – Results

Part 4 – Plant dyed yarns into products > Post details here

Assignment 2: Explore dyeing with bacteria of different fibres and bacteria

Unfortunately there wasn’t any opportunity to do this topic within the course.

We did do an extracurricular workshop, but the evidence will have to be posted when all the images of the bacteria dyed pieces are sterilised and images of them are shared.

I look forward to sharing this post with you.

Assignment 3: Bio plastics

Group work 2:

At same time as the natural dyeing, we also made plans for doing some bioplastic experiments.

We had two options: Gelatine (pig based) or Aloe based; we did a mix of the two.

Here are some photos of the processes and results of our very first experiments.

Click here to see my own developments with

- gelatin bioplastic

- agar bioplastic

- cornstarch bioplastic

Group work 3 – Kombucha Leather

Here we set up the leather to grow in this tray. I made a cover from waste fabric to protect the tray.

Unfortunately this was spoilt and thrown after a few weeks.

Recent Comments